Overview of Composite Fabric Expansion Joints

Composite fabric expansion joints are essential components in industrial systems, designed to accommodate thermal expansion, absorb vibrations, and manage movement in ductwork and piping. They protect equipment from excessive stress caused by temperature changes or pressure fluctuations, helping to ensure a smooth and safe operation. Used widely across industries like power generation, chemical processing, and HVAC, these joints are crucial in maintaining system stability and performance under challenging conditions.

Benefits of Using Composite Fabric Expansion Joints

Selecting composite fabric expansion joints from ARTES Inc. brings numerous advantages to industrial operations, including enhanced durability, flexibility, and tolerance to extreme temperatures and pressure variations. These joints not only reduce equipment strain and absorb high levels of vibration but also support system longevity by minimizing wear on surrounding components. Ideal for applications in harsh environments, composite fabric expansion joints help lower maintenance costs, improve system reliability, and contribute to greater operational safety.

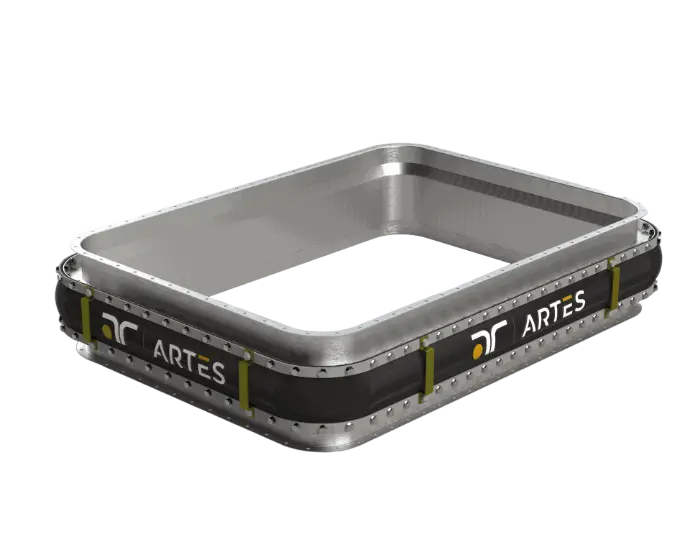

Key Features of Composite Fabric Expansion Joints

Our composite fabric expansion joints are crafted for exceptional thermal resistance, flexibility, and durability, capable of withstanding high temperatures and pressure fluctuations. These joints handle significant multi-directional movements, isolating vibrations to prevent stress on equipment. With customizable layers for added protection against chemical exposure and environmental wear, our expansion joints are the ideal choice for demanding industrial applications, providing consistent, reliable performance under high stress and ensuring a long service life.

Applications of Composite Fabric Expansion Joints

Composite fabric expansion joints are used in a wide range of applications where thermal and mechanical stresses are high. In power generation plants, they accommodate temperature shifts and manage vibration in boiler and exhaust systems. Chemical processing facilities use them to handle the demands of corrosive gases and fluids, while HVAC systems rely on them for reliable movement control in large ductwork. Whether for gas turbines, industrial furnaces, or ventilation systems, these joints are a vital part of modern infrastructure.