ARTES Inc. / Specialty Sealing

At ARTES Inc., we continue A.R. Thomson’s tradition of quality,

providing specialized sealing solutions known for durability,

dependability, and top performance. With industry expertise, we supply

a variety of seals for essential applications in sectors like chemical

processing, mining, and energy. Explore our robust, high-precision

products built to perform in the toughest environments.

Reliability

Designed for consistent performance.

Precision

Crafted with meticulous accuracy.

Adaptability

Built to adjust seamlessly.

Safety

Engineered with safety at the forefront.

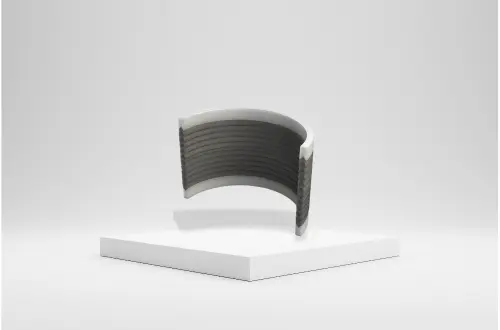

Specialty Sealing Categories

Oilfield Sealing

- Designed for high-performance applications in the demanding oil and gas sector.

- Provides reliable, leak-proof seals to endure high pressures, extreme temperatures, and aggressive media.

- Enhances operational safety and minimizes maintenance while optimizing uptime.

- Built for durability and precision in critical applications.

Rubber Molding

- Crafted to meet the stringent demands of industrial applications, from chemical processing to heavy machinery.

- Engineered for durability and resilience in high-stress environments.

- Precisely molded for optimal resistance to wear, impact, and harsh conditions.

- Enhances equipment longevity and maintains efficiency in critical operations.

Sealing Solutions

- Engineered to prevent leaks and withstand extreme conditions across industrial applications.

- Offers maximum durability against pressure, temperature, and chemical exposure.

- Optimizes performance, minimizes downtime, and extends equipment lifespan.

- Provides tailored solutions for the unique demands of critical operations.

Custom Seal Machining

- Delivers custom, high-precision components for specialized applications.

- Uses advanced machining techniques to ensure exceptional tolerance control.

- Crafted for resilience and reliability in demanding industrial environments.

- Enhances fit, minimizes wear, and guarantees quality and performance.

Looking for a customized solution?

If you can’t find the exact seal you need, rest assured—our engineering team is here to assist. At ARTES Inc., we excel in crafting custom-designed sealing solutions tailored to your specific requirements. Whether your application demands resistance to extreme temperatures, high pressures, or other specialized conditions, we can engineer a seal that meets your precise needs.

Frequently Asked Questions

Specialty sealing solutions are customized sealing products, including gaskets, O-rings, and mechanical seals, designed to meet the unique requirements of specific applications in industrial environments. Unlike standard seals, specialty seals are tailored to withstand extreme temperatures, high pressures, aggressive chemicals, and demanding physical conditions. They play a crucial role in ensuring the safety and efficiency of industrial operations by preventing leaks, reducing contamination, and protecting sensitive equipment. For industries like oil and gas, chemical processing, and power generation, specialty sealing solutions help extend the lifespan of equipment, minimize downtime, and ensure compliance with safety and environmental regulations.

Selecting the right sealing material depends on several factors, including the temperature, pressure, and type of media (fluids, gases, or chemicals) it will be exposed to. For example, PTFE is excellent for chemical resistance and high temperatures, while elastomers like NBR, HNBR, and FKM are suitable for oil and gas applications due to their compatibility with hydrocarbons. Additionally, the environmental conditions—such as exposure to UV light, ozone, or abrasion—must be considered. Consulting with a sealing specialist who understands these variables is essential, as they can recommend materials and design adjustments to ensure optimal performance and longevity for your specific needs.

Custom rubber molding involves designing and fabricating rubber parts specifically tailored to the geometry, material, and performance needs of an application. This process is necessary when standard seals or components do not meet the required specifications for fit, durability, or functionality. In industries with unique challenges, like oilfield applications or heavy-duty machinery, custom-molded rubber seals can be engineered to withstand high-pressure environments, extreme temperatures, and abrasive conditions. Custom rubber molding allows for the creation of parts that match exact dimensions, ensuring reliable sealing and extended service life in demanding environments.

Specialty seals are engineered to meet the unique challenges of specific industrial applications, providing a more precise fit, higher durability, and resistance to conditions that would degrade standard seals. By preventing leaks and maintaining tight seals under challenging conditions, these seals help maintain consistent performance and reduce wear on equipment. In industries like mining or petrochemical processing, where equipment faces harsh environments, specialty seals can prevent downtime, reduce maintenance frequency, and avoid costly repairs. By using the correct seal for each application, facilities can improve operational efficiency and extend the lifespan of their equipment.

Machining services in specialty sealing involve precision manufacturing of seals and sealing components to exact specifications. This includes cutting, shaping, and finishing materials like rubber, PTFE, and metals to create components that fit unique equipment or handle extreme conditions. Custom machining allows ARTES Inc. to produce parts that meet tight tolerances, complex geometries, or specific performance requirements that standard products can't achieve. These services are particularly beneficial for industries that require non-standard sizes, specialized materials, or designs to ensure optimal sealing performance and longevity in their applications.

Optimize Your Operations – Book a Consultation Today

Drive your operations forward with confidence.

Our Specialty Sealing Partners

Greene Tweed

Greene Tweed partners with ARTES Inc. to provide advanced, high-performance sealing solutions tailored for demanding industrial applications. Together, we deliver reliable, durable, and efficient sealing technologies that enhance the quality and longevity of our engineered solutions.

Utex

UTEX partners with ARTES Inc. to deliver exceptional sealing solutions designed for rigorous industrial environments. With a focus on durability and performance, our collaboration with UTEX enhances our product lineup, providing clients with reliable and efficient sealing options tailored to meet industry challenges.

ARTES Inc. Sealing Services

ARTES Inc. provides expert service for specialty seals, ensuring reliable performance in the most demanding environments. Our services cover inspection, maintenance, and repair, as well as custom fabrication to meet unique requirements. From high-pressure and high-temperature applications to chemical resistance, our experienced team is equipped to keep your specialty seals in optimal condition, helping to extend equipment lifespan and maintain peak operational efficiency. Choose ARTES Inc. for comprehensive, high-quality support for all your specialty sealing needs.