ARTES Inc. / Steam Traps

At ARTES Inc., we continue the A.R. Thomson tradition of excellence,

delivering high-quality steam system products known for durability,

reliability, and performance. As industry experts, we offer a range of

solutions tailored for critical steam applications in sectors such as

chemical processing, manufacturing, and power generation. Discover our

efficient, precise products designed to optimize performance in every environment.

Reliability

Designed for consistent performance.

Precision

Crafted with meticulous accuracy.

Adaptability

Built to adjust seamlessly.

Safety

Engineered with safety at the forefront.

Steam Trap Categories

Bimetallic Steam Traps

- Ideal for precision steam systems requiring adaptable condensate removal.

- Utilizes bimetallic plates to automatically adjust to temperature changes.

- Withstands thermal cycling and harsh operating environments.

- Perfect for applications needing low maintenance and reliable energy conservation.

Float and Thermostatic Steam Traps

- Combines a float mechanism for consistent condensate removal and a thermostatic element for air venting.

- Excels in applications with continuous steam usage and varying loads.

- Operates effectively in systems prone to water hammer or surging.

-

Enhances process stability and protects downstream equipment from condensate damage.

Inverted Bucket Steam Traps

- Features a time-tested inverted bucket mechanism for superior steam retention.

- Best suited for high-capacity steam systems and moderate pressure ranges.

- Known for its simple design and long-lasting performance.

- Effectively handles condensate in intermittent or cycling steam loads.

Thermodynamic Steam Traps

- Utilizes flash steam dynamics for rapid condensate discharge.

- Designed for high-pressure steam systems requiring compact solutions.

- Performs reliably in outdoor or weather-exposed environments.

- Minimizes steam loss while ensuring consistent drainage in cyclic operations.

Looking for a customized solution?

If you can’t find the exact valve you’re looking for, don’t worry—our engineering team is here to help. At ARTES Inc., we specialize in custom-designed solutions tailored to your unique specifications. Whether you need a valve for extreme temperatures, high-pressure environments, or any specialized application, we can engineer it to meet your needs.

Frequently Asked Questions

A steam trap is designed to remove condensate and non-condensable gases from steam systems without allowing steam to escape. This helps maintain the system's thermal efficiency and protects equipment from damage due to water hammer, corrosion, and erosion. There are different types of steam traps, including thermostatic, mechanical, and thermodynamic traps, each suited for specific applications based on pressure and temperature. They operate by opening to release condensate and gases when needed and closing to retain steam, ensuring that the system runs at peak efficiency while preventing the waste of valuable steam energy.

Steam systems offer numerous benefits in industrial settings, particularly for processes requiring high-efficiency heat transfer. They provide rapid heating capabilities and are highly effective at distributing energy across large distances without significant loss. Steam systems also allow for precise temperature control, essential for maintaining consistency in production processes. Additionally, steam’s high energy content makes it ideal for industries such as chemical processing, food production, and pharmaceuticals, where reliability, efficiency, and cost-effectiveness are crucial. When managed effectively, steam systems are safe, scalable, and environmentally friendly by minimizing fuel consumption and reducing emissions.

Condensate recovery is a critical component in optimizing steam system efficiency. By capturing and recycling condensate, a steam system can reuse the water that has already been heated, significantly reducing the need for additional fuel to heat fresh water. This process not only conserves water but also saves on energy costs. Furthermore, returning condensate to the boiler reduces the chemical treatment required, as the condensate is already treated water. Implementing a condensate recovery system can lead to substantial savings, extending equipment life, minimizing environmental impact, and ultimately lowering the total operational cost of the steam system.

Regular maintenance is key to the efficiency, reliability, and safety of a steam system. Essential practices include routine inspection and testing of steam traps to ensure they are operating correctly, as failing traps can result in energy loss and increased operational costs. Checking for and repairing leaks, insulating steam lines, and monitoring condensate return are also important. Additionally, regularly testing water quality and treating boiler feedwater can prevent scale and corrosion, which could otherwise damage the boiler and reduce its efficiency. Implementing a comprehensive maintenance schedule not only extends equipment lifespan but also minimizes downtime and optimizes overall system performance.

Reducing energy costs in a steam system involves a combination of efficient design, regular maintenance, and system upgrades. First, ensure proper insulation of steam lines and equipment to reduce heat loss. Using high-quality steam traps that are regularly tested and maintained prevents steam waste. Implementing a condensate recovery system can significantly cut down on water and fuel costs by recycling heated water back into the system. Additionally, optimizing boiler efficiency through proper water treatment and combustion tuning can improve fuel efficiency. In some cases, upgrading to more modern, energy-efficient components can lead to long-term savings, making the initial investment worthwhile by lowering overall energy consumption and operational costs.

Optimize Your Operations – Book a Consultation Today

Drive your operations forward with confidence.

Our Steam System Partners

Arflu

ARTES Inc. partners with Arflu to deliver a comprehensive selection of steam system solutions, including high-quality valves, strainers, and accessories. Leveraging Arflu's dedication to precision and performance, we provide dependable and customized products designed to fulfill the unique requirements of diverse industrial settings.

Islip Flow Controls Inc.

ARTES Inc. partners with Islip Flow Controls to offer an extensive range of pipeline strainers, valves, and accessories. With IFC’s commitment to quality and innovation, we provide reliable and efficient solutions tailored to meet the specific demands of various industrial applications.

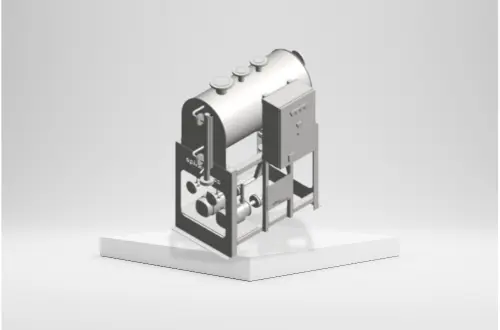

ARTES Inc. Steam System Service

At ARTES Inc., we offer comprehensive steam system services designed to keep your operations running smoothly and efficiently. Our services include installation, maintenance, troubleshooting, and optimization, ensuring that your steam systems perform at their best. With a team of skilled technicians and industry expertise, we help reduce downtime, enhance energy efficiency, and extend the lifespan of your equipment. Trust ARTES Inc. for reliable, expert support tailored to all your steam system needs.