ARTES Inc.

/ Process Instrumentation

At ARTES Inc., we deliver engineered process instrumentation solutions,

recognized for quality, reliability, and performance.

Discover our durable, precise solutions

designed to excel in every environment.

Reliability

Designed for consistent performance.

Precision

Crafted with meticulous accuracy.

Adaptability

Built to adjust seamlessly.

Safety

Engineered with safety at the forefront.

Process Instrumentation Categories

Automation

- Tailored for seamless automation and monitoring in industries such as oil and gas, chemical processing, water treatment, and power generation.

- Ensures stable operation in challenging environments with robust control solutions.

- Enhances safety, reduces downtime, and boosts productivity through reliable performance.

- Supports efficient and enduring operation in essential applications.

Process Analytics

- Designed for precision and accuracy in industries like oil and gas, chemical processing, water treatment, and power generation.

- Facilitates real-time monitoring with dependable data, even in challenging conditions.

- Enhances operational safety and minimizes interruptions with consistent performance.

- Delivers durable, efficient solutions for critical applications.

Process Measurement

- Offers consistent and efficient temperature control for industries like oil and gas, chemical processing, food production, and power generation.

- Provides precise heat regulation, ensuring dependable performance in rigorous conditions.

- Boosts safety and minimizes downtime with reliable efficiency.

- Delivers durable, high-performance heating systems for demanding applications.

Thermal Solutions

- Designed for reliable motion control in industries such as oil and gas, chemical processing, water treatment, and power generation.

- Enables precise movement and positioning for efficient, remote operation in tough conditions.

- Enhances safety and minimizes downtime with dependable performance.

- Built for long-lasting durability and productivity in critical applications.

Looking for a customized solution?

If you can’t find the exact process instrumentation solution you’re looking for, don’t worry—our engineering team is ready to assist. At ARTES Inc., we specialize in custom-designed solutions tailored to your specific requirements. Whether you need instrumentation for extreme temperatures, high-pressure settings, or any unique application, we can engineer it to meet your needs.

Frequently Asked Questions

Process instrumentation refers to the tools and devices used to measure, control, and monitor variables within an industrial process, such as temperature, pressure, flow, and level. These instruments are essential for maintaining optimal conditions, ensuring product quality, and safeguarding equipment. In industries like oil and gas, chemical processing, and power generation, precise control over process variables is critical to maintaining efficiency, safety, and regulatory compliance. Proper instrumentation allows operators to track real-time performance, make timely adjustments, and detect issues before they lead to costly downtime, making it an invaluable component of industrial systems.

Choosing the right instrumentation involves several factors, including the process conditions (e.g., temperature, pressure, and flow rate), the specific industry requirements, and the environmental conditions. For example, in high-temperature applications, sensors and transmitters must withstand extreme heat without losing accuracy. In corrosive environments, instruments made of resistant materials are necessary to prevent degradation. Consulting with an experienced engineering team or instrumentation specialist can also help identify the best solutions for unique needs, ensuring reliable and long-lasting performance.

Digital instrumentation offers several advantages over traditional analog systems, including higher accuracy, faster response times, and more comprehensive data collection. Digital instruments can often communicate through networks, allowing for real-time monitoring and remote control, which can be crucial in large-scale or hazardous environments. Additionally, digital systems typically support advanced diagnostics, enabling predictive maintenance that reduces downtime. With improved data analytics capabilities, digital instrumentation helps facilities optimize operations, streamline reporting, and comply more easily with industry standards and regulations.

Calibration is essential for maintaining the accuracy and reliability of process instrumentation. The frequency of calibration depends on the instrument type, the process conditions, and industry standards; many systems require calibration at least annually, while critical applications may need more frequent checks. Regular calibration ensures that instruments provide accurate data, which is vital for process control and quality assurance. Without proper calibration, deviations can occur, leading to inefficiencies, compromised safety, or product quality issues, so adherence to a consistent calibration schedule is recommended for optimal performance.

Process instrumentation plays a critical role in monitoring hazardous variables such as pressure and temperature, helping to prevent unsafe conditions that could lead to equipment failure or accidents. Instruments like pressure transmitters, flow meters, and temperature sensors detect and communicate potential issues in real time, allowing for immediate intervention. Additionally, regulatory bodies often require precise control over environmental conditions; process instrumentation enables facilities to meet these standards, providing necessary data for compliance reporting. This focus on safety and compliance helps protect both personnel and the environment, ensuring responsible industrial operations.

Optimize Your Operations – Book a Consultation Today

Drive your operations forward with confidence.

Our Instrumentation Partners

Krohne

ARTES Inc. proudly partners with KROHNE to provide advanced analytical solutions for precise process measurement and control. With KROHNE’s expertise in flow, level, and analytical instrumentation, we deliver industry-leading technology for reliable performance in any application. Trust ARTES Inc. and KROHNE for top-tier analytical products that support your operational goals.

Watlow

ARTES Inc. partners with Watlow to bring you premium heating solutions for precise temperature control. Known for their expertise in industrial heating, Watlow’s products enhance reliability and efficiency across diverse applications. Rely on ARTES Inc. and Watlow for innovative heating solutions that drive operational success.

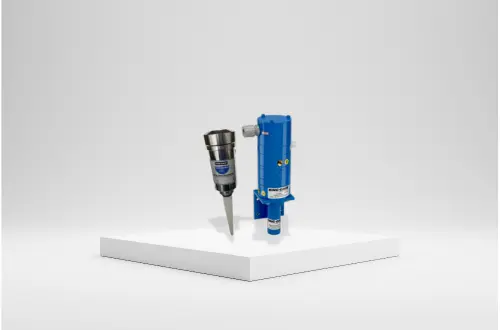

ITT

ARTES Inc. partners with ITT to deliver precise and reliable instrumentation solutions for flow, pressure, and level measurement. Together, we bring industry-leading technology that enhances control, accuracy, and efficiency in critical industrial processes.

Pulsar Measurement

Pulsar Measurement partners with ARTES Inc. to provide advanced solutions for flow and level monitoring, ensuring accuracy and reliability in complex industrial applications. Together, we deliver cutting-edge measurement technology that supports efficient and effective process management.

Reotemp

REOTEMP partners with ARTES Inc. to offer reliable, high-quality process instrumentation for temperature and pressure measurement. Together, we provide industrial solutions that ensure precision, durability, and optimal performance in demanding environments.

Weintek

Weintek partners with ARTES Inc. to deliver advanced HMI solutions for precise and efficient process instrumentation. Together, we provide intuitive, reliable systems that streamline control and enhance productivity across industrial applications.