Engineered Solutions

From Concept to Implementation.

At A.R. Thomson Engineered Solutions, we deliver tailored engineering solutions designed to meet the unique needs of your industry.

Our expertise in system design, product development, and advanced testing ensures exceptional performance and reliability for every project.

Commitment to Excellence

Innovation and Performance

Application Engineering

Professionally and Technically Certified

Professional Engineers and other technically certified staff design to application finding the best solution, balancing budget considerations with functionality.

In-House Services

In House PMI (Positive Material Identification), LPI (Liquid Penetrant Inspection), failure analysis, and metallographic polishing and analysis.

We also offer hydrostatic-testing and destructive testing up to 100 ksi, ensuring thorough evaluation and quality assurance for all applications.

Product Design

Local Engineering

Our local engineering provides customized design solutions, leveraging in-depth knowledge of regional standards and requirements.

Our Engineers operate under permit to practice in all jurisdictions.

Designed for Movement

Products that accommodate and enhance movement within systems. For optimal functionality, durability, and efficiency for components subject to dynamic forces and motion.

Hose, Expansion Joints, Compensator Bellows

Our products are engineered for reliability and longevity, providing effective solutions for movement and vibration management.

Optimize Your Operations – Get a Consultation Today

Drive your operations forward with confidence.

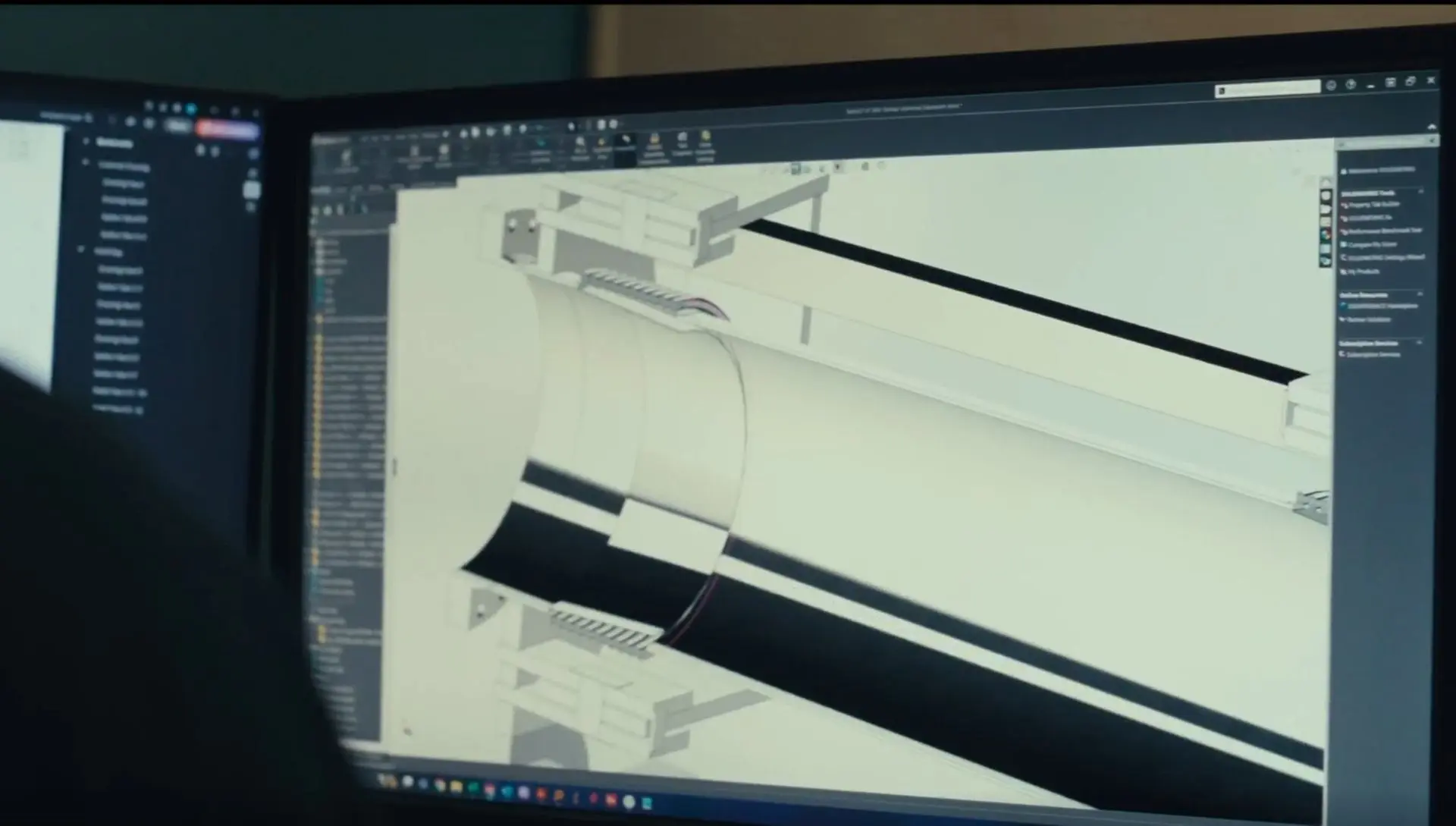

Product Development

Design Prototype Test Equipment

We take a holistic approach to product development by not only designing innovative products but also engineering and constructing the specialized equipment needed for their production and testing.

This integrated process ensures that every aspect of our product, from conception to manufacturing and quality assurance, is meticulously crafted to meet the highest standards of performance and reliability.

Design Manufacturing Equipment

Designing manufacturing equipment that meets precise specifications and industry standards.

Prototype Testing

Thorough prototype testing services including cycle testing, pressure testing, and helium leak testing. We ensure prototypes are rigorously evaluated to meet performance criteria and industry standards, identifying any issues before full-scale production.

Process Control Systems

System Design and Integration

Expert engineers design and integrate customized process control systems tailored to specific industry needs, ensuring optimal performance and efficiency.

Advanced Calibration and Testing

Comprehensive calibration and testing services to validate system accuracy, including functional testing and performance validation to meet industry standards.

Remote Monitoring and Support

24/7 remote monitoring and technical support services to ensure continuous system operation and timely issue resolution, enhancing system reliability and reducing downtime.